May 30, 2018 · In particular, we will focus on disposable microfluidic devices and discuss common methods of fabrication, on-chip functions, and their usage in bioanalytical applications. We refer readers to other review articles for more in-depth coverage of specific areas ( 1–3 ); each section below also contains references to appropriate topical reviews.

Feb 2, 2022 · Let's say Nurse Janelle is preparing to administer a vaccination to a client while using proper, medical aseptic technique. She washes her hands for 20 seconds before bringing the syringe and vial

Treatment by sterilization through autoclaving process: If an autoclave is available, use it to effectively sterilize discarded COVID-19 vaccine vials before final disposal. First wash your hands and put on surgical gloves. Place the vials inside of the autoclave, following specified instructions for using the equipment.

After removal of blood and tissue, the tips of surgical instruments are placed into the hot glass beads for approximately 10-15 seconds. Only the tips of the instruments are re-sterilized in this process. Instrument tips become extremely hot and must be cooled before use. Glass bead sterilizers may be used between animals when one set of

Mar 31, 2017 · Various recommendations for the prevention of VAP include (1) appropriate cleaning, disinfection, and sterilization of ventilator equipment, (2) maintenance of ventilator circuits, and (3) routine care of patients requiring ventilation. 14 The cleaning, disinfection, and sterilization of the equipment have been discussed earlier in the chapter

High-level disinfection of arthroscopes, laparoscopes, and cystoscope should be followed by a sterile water rinse. 7.h. Phase out endoscopes that are critical items (e.g., arthroscopes, laparoscopes) but cannot be steam sterilized. Replace these endoscopes with steam sterilizable instruments when feasible.

Oct 18, 2016 · Sterilizer manufacturers validate their sterilization cycles using biological indicators containing bacterial spores. For this reason, routine sterilizer efficacy monitoring in healthcare facilities should also be con-ducted using BIs. The spore that is the most resistant to the steam sterilization process is Geobacillus stearothermophilus.

bled and packaged, they can be sterilized. Steam sterilization is the most popular — and preferred — method of steril-ization because it doesn’t use potentially harmful chemicals. The CDC recommends this method for all items that can withstand heat and moisture.14 To prepare for steam sterilization, an SPD technician

Oct 30, 2022 · The usual procedure is to heat at 1.1 kilograms/square centimeter (kg/cm 2) [15 pounds/square inch (lb/in 2 )] steam pressure, which yields a temperature of 121°C. At 121°C, the time of autoclaving to achieve sterilization is generally considered to be 15-20 min, depending on the volume of the load.

Jun 6, 2023 · Autoclave: Parts, Principle, Procedure, Types, Uses. An autoclave is a machine that provides a physical method of sterilization by killing bacteria, viruses, and even spores present in the material put inside of the vessel using steam under pressure. Autoclave sterilizes the materials by heating them up to a particular temperature for a

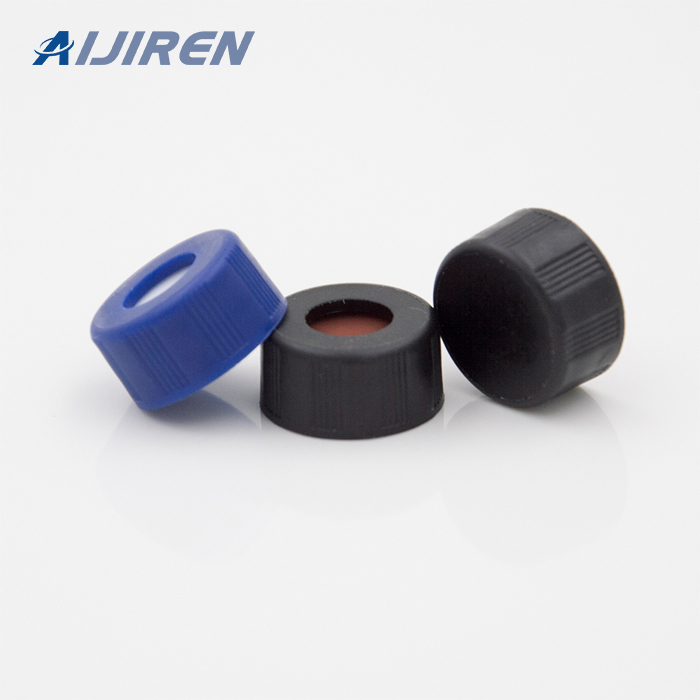

1. Prepare the items for sterilization (Fig #1): glass bottles with caps - washed, air-dried completely, capped with cap half-loosened, autoclave tape on top of lid. plastic large centrifuge bottles with caps - washed, air-dried completely, capped with cap very loosely covering the opening and NOT tightened, autoclave tape on top of lid.

Like all sterilization processes, steam sterilization has some deleterious effects on some materials, including corrosion and combustion of lubricants associated with dental handpieces 212; reduction in ability to transmit light associated with laryngoscopes 828; and increased hardening time (5.6 fold) with plaster-cast 829.

Dec 7, 2020 · The first factor is the stopper; formulation, design, siliconization, and sterilization have an effect. Generally, the softer the stopper and the thinner the diaphragm, the lower the level of cores/fragments. Also, siliconization may lower the level of cores/fragments. Regarding sterilization, steam processed stoppers have lower levels as

Single-use Vials,49 all from the Centers for Disease Control and Prevention (CDC), serve as the backbone for most infec - tion prevention practices in the United States. Safe infusion, injection, and medication vial practices have been addressed by CMS50 and the Association for Professionals in Infection

proper orientation of the barcode label on the cryovial. 2.3 There will also be special QC ID labels for the blind duplicate samples. See section 6.7 for further information about this procedure. 2.4 Blood samples must be precisely labeled throughout the collection and processing stages to ensure they are correctly coded. Always pre-label