Sep 2, 2019 · Container closure integrity (CCI) plays an important role in maintaining the sterility and stability of sterile injectable products. The defects that cause a sterile vial to leak are not necessarily detectable by a visual inspection process. Examples of such defects are those that are hidden by the crimp, microscopic cracks and scratches in the

Apr 12, 2015 · SNAP FIT CLOSURES • Snap is any clasp or fastener that closes with a click. • When the closure is in place, some resilient part of the closure system that is in contact with the container remains deformed, & provides a seal as it attempts to return to its original dimensions. • For opening, the top is designed to pry off or break off, or

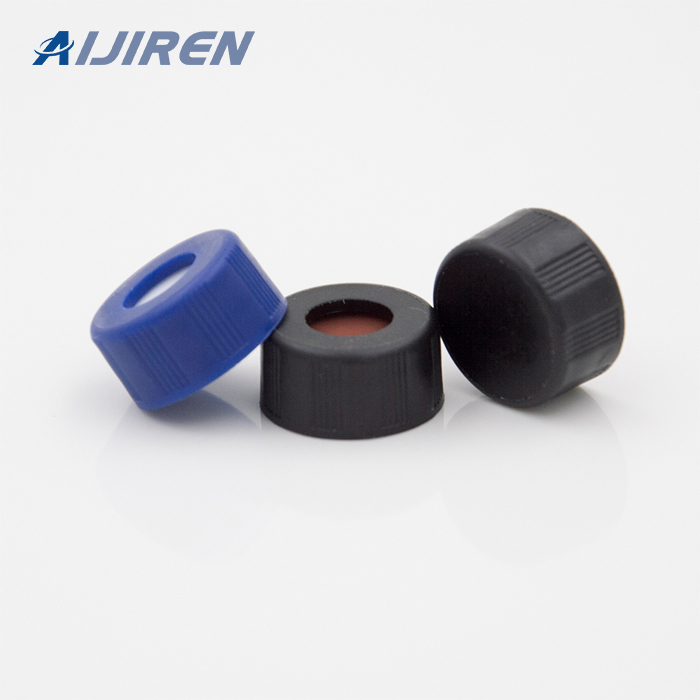

Pharmaceutical Vial Seals. Seals are a crucial part of a vial system. The selection of an appropriate seal is critical to ensuring container closure integrity, drug protection, user convenience and safety.

The integral membrane closure is often seen as a more economical approach to vial closures when analyses are a little less demanding. That doesn’t mean there isn’t a need for innovation. With the AVCS technology design aspects of the open top cap built-in, the integral membrane closure also provides a halogen and rubber-free sample handling

intended packaging system. Furthermore, a closure’s functional performance assessment outcome can be affected by the design, processing, and assembly of that packaging system. For example, closure processing parameters and vial package sealing forces directly impact parenteral vial packaging integrity results.

There are no tools to measure torque for a small closure such as the 9-mm cap. Utilizing an innovative design process, such as the Advance Vial Closure System (AVCS) allows bench chemists and sample prep technicians to remove the subjectiveness out of achieving the optimal compression when sealing a vial.

designed as part of the Advanced Vial Closure System (AVCS), and remove subjectivity around achieving the optimal seal compression when closing a vial. As an integral component of AVCS technology, SureStop vials offer the sealing and performance characteristics of a crimp top vial and the versatility and convenience of a threaded vial.

Feb 1, 2016 · In this review, the health authority requirements and expectations related to container closure system quality and container closure integrity are summarized. The pharmaceutical vial, the rubber stopper, and the crimp cap are described.

Push-Fit Vial Closure System. RayDyLyo ® is the innovative alternative to aluminium crimp seals. Manufactured from plastic, and available sterile, the RayDyLyo® cap allows for simple push-fit closing of injection vials and is suitable for development stage right up to full-scale automated production. Request sample Save to favourites.

are used, a bracketing approach (smallest-largest) may be used. 3. Filling speed-generally should be set at production filling range. However if higher or lower speeds present “worst case” conditions those maybe used. Eg. Bracketing approach of highest speed with smallest unit (operational challenge-PM generation) or

three places. The primary seal is between the flange of the stopper and the top surface of the glass, this is the land seal. The other seals are located between the plug of the stopper and the inner surface of the neck of the vials and at the transition between the plug and the flange. Image courtesy of West Pharmaceutical

and services includes the most innovative elastomer formulations, coatings, aluminum seals, and processing technologies. Datwyler also offers one of the most extensive product portfolios for vial applications in the present pharmaceutical and biotech markets worldwide. Datwyler’s experience, knowledge, and engineering expertise translates into:

The current USP <1207> chapter titled ‘Package Integrity Evaluation – Sterile Products’ was implemented in late 2016 and represents the most thorough guidance document to date on container closure integrity concepts for sterile injectable products. The chapter gives an overview of CCI testing technologies and approaches for a CCI control

are designed as part of the Advanced Vial Closure System (AVCS), and remove any subjectivity around achieving the optimal compression when sealing a vial. As an integral component of AVCS technology, SureStop vials offer the sealing and performance characteristics of a crimp top vial and the versatility properties of a threaded vial.

The integral membrane closure is often seen as a more economical approach to vial closures when analyses are a little less demanding. That doesn’t mean there isn’t a need for innovation. With the AVCS technology design aspects of the open top cap built-in, the integral membrane closure also provides a halogen and rubber-free sample handling